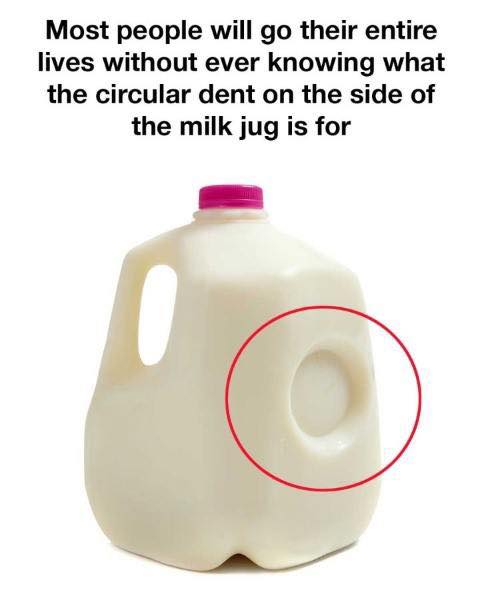

Most people hardly notice the small, round dent on the side of a plastic milk jug. It might seem like a manufacturing flaw or a random detail, but this subtle indentation is actually a smart design feature with several important purposes—ranging from safety and durability to sustainability and convenience. It’s a great example of thoughtful engineering behind everyday objects.

One main function of the dent is to manage pressure inside the jug. Milk jugs are usually made from high-density polyethylene (HDPE), a lightweight and cost-effective plastic. Since these containers have thin walls to save material and reduce weight, they are prone to pressure changes caused by temperature or movement. The dent acts as a flexible zone that allows the jug to expand and contract without cracking or leaking. Similar to an expansion joint in a bridge, this area absorbs pressure shifts to keep the jug intact. That slight pop you might hear or feel when setting down the jug? That’s the dent doing its job.

The dent also serves as a built-in shock absorber. Milk jugs are often dropped or bumped during handling, whether at the store or at home. Without this design feature, impacts could cause cracks or spills. Much like a car’s crumple zone, the dent helps absorb impact energy and reduce damage.

Continue reading on next page…