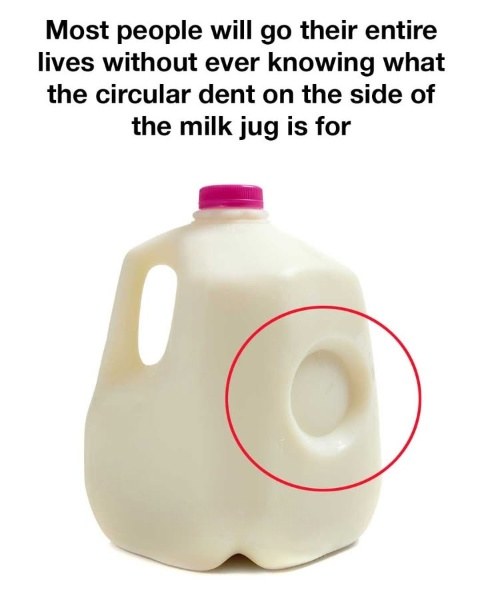

Many people have noticed the circular indentation on the side of a plastic milk jug and wondered why it is there. At first glance, it might look like a manufacturing flaw or a design detail added without much thought. In reality, that small dent serves an important purpose, and understanding it can change the way you look at everyday packaging.

The indentation is part of the jug’s safety and structural design. It helps regulate pressure, improves durability, and strengthens the container without increasing the amount of plastic used. It may seem like a simple feature, but it solves several problems at once.

Temperature changes are a major reason the dent exists. Milk travels through different environments before reaching your refrigerator — from warm loading areas to chilled trucks, then into grocery stores and finally into a home kitchen. As temperatures shift, the liquid inside expands and contracts. Without a flexible area to absorb that pressure, the jug could swell, crack, or burst if the milk freezes and expands. The indentation is designed to flex outward when pressure rises and return to its original position once the temperature stabilizes. This small feature helps the jug withstand everyday conditions during shipping and storage.

The dent also contributes to the jug’s strength. Milk containers are frequently moved, stacked, and handled quickly, and accidents can happen during transport or at home. The indentation helps absorb impact by distributing force more evenly across the surface of the jug. This reduces the chance of cracking and prevents unnecessary waste. A single damaged jug can cause a large mess, so this added protection is useful for both stores and consumers.

Continue reading on the next page…